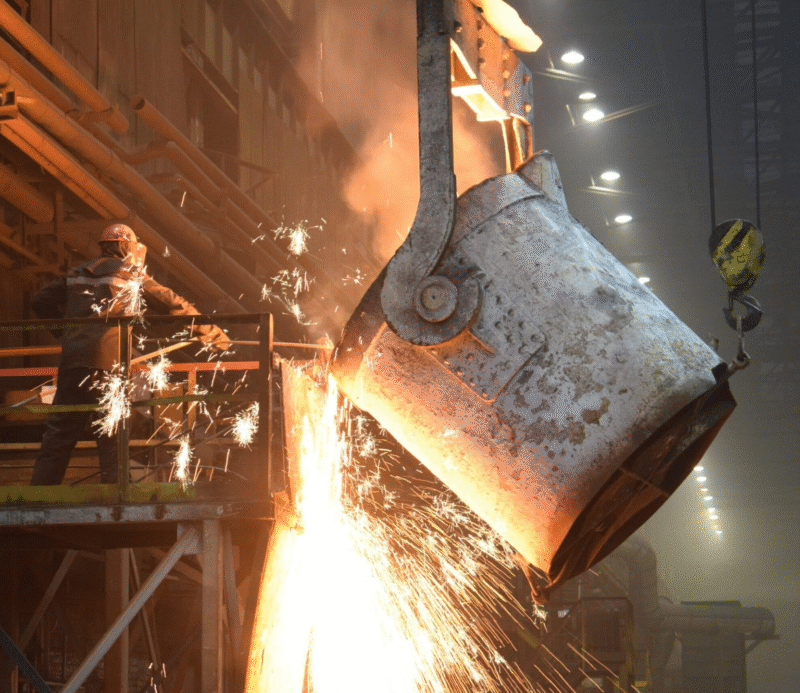

What is Foundry Gilsonite?

Foundry Gilsonite is a specialized grade of natural asphalt or uintaite used as an additive in foundry sand mixtures for metal casting. Its unique high carbon content, volatility, and binding ability make it an essential material for producing clean, precise castings with minimal surface defects.

Gilsonite is added to green sand and resin-coated sand systems to improve mold and core performance in casting iron, steel, aluminum, and non-ferrous metals.

Properties of Foundry Gilsonite

| Property | Function in Foundry |

|---|---|

| High Fixed Carbon | Improves casting finish and surface smoothness |

| Volatile Content | Reduces gas defects and burn-on issues |

| Thermoplastic Binder | Enhances mold cohesion and flowability |

| Low Ash Content | Minimizes slag and residue in castings |

| Natural Lubrication | Improves mold release and collapsibility |

Foundry Grade Gilsonite offers unique properties that make it a valuable additive in the foundry industry. When added to sand molds or cores, it provides several benefits such as improved mold strength, reduced gas defects, enhanced surface finish, and increased dimensional accuracy.

Benefits of Gilsonite in Foundry Applications

🧱 1. Improves Surface Finish

Gilsonite produces smooth and clean casting surfaces by generating a reducing atmosphere that prevents metal penetration.

🧪 2. Reduces Casting Defects

Its volatilization at high temperatures helps create a protective gas layer that minimizes veining, scabbing, and burn-in.

⚙️ 3. Enhances Mold Strength

Foundry Gilsonite acts as a binder, improving the compression strength and integrity of green sand molds and cores.

🔧 4. Reduces Additive Costs

It can partially or fully replace other carbonaceous additives like sea coal, offering better performance at lower dosages.

One of the key advantages of Foundry Grade Gilsonite is its ability to improve mold strength. It acts as a binder, enhancing the cohesion and adhesion of sand particles in the mold or core. This results in higher green strength, which is the strength of the mold before it is exposed to high temperatures during casting. Improved mold strength helps prevent mold erosion, deformation, and breakage, leading to better casting quality.

Another significant benefit of Foundry Grade Gilsonite is its ability to increase dimensional accuracy. It helps reduce the expansion and contraction of the mold or core during the casting process. This ensures that the final castings maintain the desired shape, size, and dimensional tolerances, resulting in improved precision and consistency.

Furthermore, Gilsonite reduces the formation of gas defects in castings. It acts as a carbon source, releasing carbonaceous gases during the casting process. These gases create a protective atmosphere in the mold or core, preventing the penetration of air and reducing the occurrence of defects such as porosity and gas inclusions. This improves the overall integrity and quality of the castings.

Additionally, Foundry Grade Gilsonite enhances the surface finish of castings. It forms a thin, continuous film on the mold or core surface, providing a smooth and uniform texture to the castings. This improves the appearance and aesthetics of the final product, making it more visually appealing.

Applications of Foundry Gilsonite

| Foundry Process | Role of Gilsonite |

|---|---|

| Green Sand Casting | Improves mold strength and collapsibility |

| Resin-Coated Sand Systems | Enhances core surface finish |

| Iron & Steel Casting | Prevents burn-on, reduces cleaning effort |

| Non-Ferrous Metal Casting | Produces high-definition, low-defect castings |

When using Foundry Grade Gilsonite, it is important to consider the specific foundry process, sand formulation, and desired casting objectives. The dosage and blending process may vary depending on these factors, and it is recommended to follow the manufacturer’s guidelines or consult with experts in foundry operations.

FAQs – Foundry Gilsonite

What type of metals can use Gilsonite in casting?

Gilsonite is effective in ferrous (iron, steel) and non-ferrous (aluminum, brass) metal casting.

How is Gilsonite used in green sand?

It is mixed with bentonite clay and silica sand in small percentages (typically 1–5%) to improve mold performance.

Is Natural asphalt safe to use in foundries?

Yes. It is non-toxic and naturally occurring, though like all carbon-based additives, dust handling precautions should be taken.

What mesh sizes are available?

Common sizes include 70, 100, and 200 mesh, depending on the desired burn-off rate and fineness.

Conclusion – Why Foundry Gilsonite is Essential

Foundry Gilsonite is a proven performance enhancer for modern metal casting. Its benefits include:

-

✔️ Cleaner, smoother casting surfaces

-

✔️ Reduced gas-related casting defects

-

✔️ Improved mold and core strength

-

✔️ Cost-effective performance in various metal types

From automotive parts to heavy industrial castings, Gilsonite helps foundries achieve precision, durability, and efficiency.

Foundry Grade Gilsonite is a valuable additive that enhances foundry applications in the metal casting industry. Its unique properties contribute to improved mold strength, reduced gas defects, enhanced surface finish, and increased dimensional accuracy. By incorporating Foundry Grade Gilsonite into sand molds or cores, foundries can achieve higher quality castings with improved strength, aesthetics, and precision.

-

Foundry grade Gilsonite additive

-

Gilsonite for metal casting

-

Natural asphalt for foundries

-

Gilsonite in mold formulation

- Carbon additive for casting

🏭 Need High-Performance Foundry Gilsonite?

We offer:

-

✔️ High carbon, low ash Gilsonite

-

✔️ Custom mesh sizes for foundry use

-

✔️ Technical support and bulk export

📩 Contact us now for specifications, samples, or expert guidance! For more information or to place an order, please contact PUB-Ltd sales team @ Contact Us. PUB-Ltd as your Premium Gilsonite Supplier. Our Expert will be in touch with you to guide you about the Foundry grade Gilsonite, that can be produced according to your project requirements.