What is PE wax? Benefits, Uses, Manufacturing & More

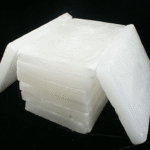

PE wax (Polyethylene wax) is a synthetic wax derived from the polymerization of ethylene gas. It is a versatile and widely used material known for its excellent lubricating and anti-blocking properties. Polyethylene wax is produced in various forms, including powders, flakes, and pastilles, to suit different applications.

One of the key characteristics of PE wax is its low melting point, typically ranging from 100 to 140 degrees Celsius (212 to 284 degrees Fahrenheit). This low melting point allows it to function as an effective lubricant, reducing friction and enhancing the flow properties of various materials.

What is PE Wax?

PE wax, short for polyethylene wax, is a low molecular weight polymer derived from polyethylene. It appears as a white, odorless, waxy solid and is highly valued in industries such as plastics, rubber, coatings, inks, and cosmetics for its lubricating, dispersing, and modifying properties.

With excellent chemical resistance, thermal stability, and compatibility, PE wax plays a crucial role in modern manufacturing processes.

Quick Overview Table

| Property | Details |

|---|---|

| Chemical Name | PE Wax (Polyethylene Wax) |

| Appearance | White solid (flakes, granules, or powder) |

| Melting Point | 85°C – 140°C (depending on grade) |

| Molecular Weight | 1,000 – 10,000 g/mol |

| Density | 0.92 – 0.98 g/cm³ |

| Solubility | Insoluble in water; soluble in hydrocarbons and oils |

| Form | Flakes, pastilles, powder, emulsions |

| Odor | Odorless |

| CAS Number | 9002-88-4 |

How is PE Wax Made?

PE wax is produced using several methods, each influencing its performance profile:

1. Thermal Cracking of HDPE

Breaks down high-density polyethylene into shorter molecular chains to create wax.

2. Direct Polymerization of Ethylene

Polymerizes ethylene under specific conditions to produce low molecular weight wax directly.

3. Refinement from Polyethylene Production

Recovered and refined as a by-product during PE resin manufacturing.

These methods create different grades of PE wax for targeted industrial use.

Key Benefits of PE Wax

✅ Superior Lubrication

Improves processing of plastics and reduces surface friction in rubber and extrusion systems.

✅ High Thermal Stability

Withstands elevated processing temperatures without degradation.

✅ Excellent Chemical Resistance

Highly resistant to water, acids, and alkalis.

✅ Enhances Gloss and Slip

Used in coatings and inks to improve finish, rub resistance, and surface glide.

✅ Broad Compatibility

Blends easily with various resins, pigments, and other waxes.

Common Applications of PE Wax

| Industry | Application |

|---|---|

| Plastics | Lubricant and dispersing agent in PVC, masterbatches, compounding |

| Rubber | Processing aid and mold release agent |

| Coatings | Adds abrasion resistance and surface smoothness |

| Inks | Enhances print durability and anti-blocking properties |

| Cosmetics | Binder, thickener, and emollient in skincare and lip products |

| Textiles | Imparts softness and water repellency |

| Adhesives | Improves hot-melt adhesives’ thermal behavior and flow |

PE wax finds extensive use as an internal and external lubricant in the plastics industry. It is commonly added to plastic resins during processing to improve their melt flow, mold release, and surface finish. By reducing the friction between polymer chains, polyethylene wax helps prevent sticking and enhances the processability of plastics.

In the coatings and inks industry, PE wax acts as a matting agent and surface modifier. It imparts a matte appearance to coatings and helps improve scratch resistance and anti-blocking properties.

Additionally, PE wax can enhance the dispersibility and stability of pigments and fillers in coatings and inks formulations.

Polyethylene wax also serves as a processing aid in the rubber industry. It improves the flow characteristics and mold release properties of rubber compounds, facilitating their processing and enhancing the surface finish of the final rubber products.

In the paper and packaging industry, polyethylene wax is used as a coating material. It provides a protective layer that enhances the moisture resistance, printability, and smoothness of papers and packaging materials. PE wax coatings can also improve the heat-sealing properties of packaging films.

Furthermore, PE wax finds applications in the personal care and cosmetic industry. It is used as a thickening agent, emollient, and gloss enhancer in various formulations such as lip balms, lotions, and creams. Its lubricating properties help provide smooth application and a desirable texture to these products.

PE wax (Polyethylene wax) is considered a safe and non-toxic material, making it suitable for use in various consumer products. It is chemically stable, compatible with a wide range of materials, and has a long shelf life.

Technical Grades of PE Wax

| Type | Description | Typical Use |

|---|---|---|

| Micronized PE Wax | Fine powder for better dispersion | Inks, coatings, personal care |

| Oxidized PE Wax | Contains polar functional groups for emulsification | Water-based coatings, polishes |

| High Molecular Weight | Hard, crystalline wax with superior thermal properties | Plastic processing, pipe extrusion |

| Low Molecular Weight | Softer wax for easier blending and compatibility | Lubricants, wax emulsions |

Manufacturer & Supplier Info

When sourcing PE wax, working with a reputable, quality-focused supplier ensures consistency and performance.

🔹 Trusted Global Suppliers:

-

BASF – Polyethylene wax solutions for high-performance industrial applications

-

Honeywell – ACX oxidized Polyethylene waxes for adhesives and coatings

-

Clariant – Ceridust® micronized Polyethylene waxes for inks and plastics

-

Trecora / SI Group – Custom formulations for specialty applications

-

Pars Universal Bitumen – Premier supplier of industrial waxes, including Polyethylene wax, paraffin, and slack wax

Why Choose PE Wax from Pars Universal Bitumen?

At Pars Universal Bitumen, we offer a wide range of Polyethylene wax products suitable for various industries and performance needs.

Why Our Clients Prefer Us:

-

✅ ISO-Certified Manufacturing

-

✅ Wide Range of Grades (oxidized, micronized, custom blends)

-

✅ High Purity and Batch Consistency

-

✅ Competitive Wholesale Pricing

-

✅ Global Shipping with On-Time Delivery

Whether you’re in plastics, printing, cosmetics, or adhesives, our PE wax solutions are engineered to help you improve product performance and production efficiency.

FAQs About PE Wax

❓ Is PE wax safe in cosmetic formulations?

Yes, cosmetic-grade polyethylene wax is non-toxic, stable, and widely used in skin care, lip products, and balms.

❓ What’s the difference between PE wax and paraffin wax?

Polyethylene wax is derived from polyethylene and has higher chemical and thermal resistance than paraffin, which is softer and less durable.

❓ Can PE wax be used in water-based systems?

Yes—oxidized or emulsified polyethylene wax can be incorporated into water-based coatings and polishes.

❓ Is PE wax biodegradable?

Conventional Polyethylene wax is not biodegradable, but sustainable and bio-based alternatives are emerging.

❓ How can I choose the right PE wax grade?

The right grade depends on your processing temperature, application, and compatibility. Our technical experts at Pars Universal Bitumen can help.

Conclusion

PE wax (Polyethylene wax) is a versatile and essential material used in a wide array of industries, thanks to its thermal stability, lubricity, chemical resistance, and ease of formulation. Whether you’re manufacturing inks, enhancing plastics, or formulating personal care products, polyethylene wax delivers reliable performance.

With a variety of grades and customization options, Pars Universal Bitumen is your ideal partner for high-quality polyethylene wax solutions.

✅ Call to Pars Universal Bitumen

🔍 Looking for High-Performance PE Wax for Your Industry?

Pars Universal Bitumen offers:

-

Custom and standard PE wax grades

-

Bulk pricing and flexible packaging

-

Fast global shipping & expert support

📩 Contact us now to get a quote or technical consultation.

👉 [Request a Quote] | 📘 [View PE Wax Grades]

📧 Email: [email protected]

📞 Phone: +971 4 878 2031

🌐 Visit: Pub-ltd

We offer high-quality PE wax (Polyethylene wax) with custom packaging and fast international delivery. If you have any further questions, don’t hesitate to contact us.