🏭 What is Industrial Petroleum Jelly? Uses, Benefits & Applications

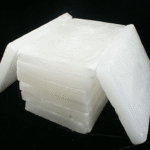

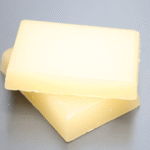

Industrial petroleum jelly is a semi-solid mixture of hydrocarbons derived from petroleum, specially formulated for industrial and technical use. Unlike cosmetic or medical-grade versions, industrial petroleum jelly is not intended for human application but serves as a lubricant, corrosion inhibitor, release agent, and protective coating in a wide range of industries.

Industrial petroleum jelly, also known as Technical petroleum jelly or Heavy petroleum jelly, is a specialized form of petroleum jelly that is specifically formulated for industrial applications. It is a semi-solid mixture derived from petroleum and is widely used in various industries for its unique properties.

🧪 What Is Industrial Petroleum Jelly Made Of?

Industrial-grade petroleum jelly is composed of high molecular weight hydrocarbons. It is generally less refined than medical or cosmetic versions and may contain:

-

Petrolatum base

-

Paraffinic and microcrystalline waxes

-

Mineral oils

-

Stabilizers or antioxidants (in some formulations)

It typically appears as a white to yellowish translucent gel, with a higher melting point and greater viscosity than cosmetic-grade products.

🛠️ Key Industrial Uses of Petroleum Jelly

Technical petroleum jelly plays a vital role in multiple sectors due to its moisture resistance, lubricating ability, and inert chemical nature:

1. Machinery & Equipment Lubrication

Used as a light-duty lubricant for moving parts in low-friction environments such as:

-

Conveyor systems

-

Mechanical linkages

-

Hinges and shafts

It reduces wear, protects against rust, and performs well in dusty or dry environments.

One of the primary uses of industrial petroleum jelly is as a lubricant. Its high viscosity and excellent lubricating properties make it ideal for reducing friction and wear in industrial machinery and equipment. Technical petroleum jelly is commonly used in bearings, gears, valves, and other mechanical components to ensure smooth operation and extend their lifespan.

2. Corrosion Protection

Acts as a barrier against moisture, oxygen, and salt air. Common in:

-

Metal part storage and shipping

-

Marine environments (protects electrical terminals)

-

Tools, valves, and battery terminals

3. Cable and Wire Coating

Applied to electrical cables, fiber optics, and telecommunication wires to:

-

Prevent oxidation

-

Protect against water ingress

-

Enhance insulation over time

4. Mold Release Agent

Facilitates smooth release of molded parts in:

-

Plastic injection molding

-

Rubber and polyurethane casting

-

Concrete formwork

5. Leather & Rubber Treatment

Used to condition leather and preserve rubber, especially in:

-

Conveyor belts

-

Rubber seals and gaskets

-

Industrial footwear and glov

Industrial petroleum jelly finds application in the rubber and plastics industry. It can be used as a processing aid in the manufacturing of rubber products, such as seals, gaskets, and O-rings. It improves the flow properties of rubber compounds and aids in the molding and extrusion processes. Technical petroleum jelly can also be used as a plasticizer in the production of plastic materials, enhancing their flexibility and workability.

6. Oil & Gas Industry Applications

Acts as a sealant and corrosion inhibitor in:

-

Valve maintenance

-

Drill pipe threads

-

Joint protection

Industrial petroleum jelly is also used as a rust preventive and corrosion inhibitor. Its ability to adhere to metal surfaces and provide a protective coating helps to prevent oxidation and corrosion. It is commonly applied to metal parts, tools, and equipment that are susceptible to rust and corrosion, providing long-term protection.

Characteristics of Industrial Petroleum Jelly

| Property | Specification |

|---|---|

| Appearance | Yellowish or white semi-solid |

| Melting Point | 50–60°C (varies by grade) |

| Water Solubility | Insoluble |

| Viscosity (at 100°C) | High |

| Odor | Slight petroleum scent |

| Shelf Life | 3–5 years (stored properly) |

🔍 Industrial vs. Medical vs. Cosmetic Petroleum Jelly

| Feature | Industrial | Medical | Cosmetic |

|---|---|---|---|

| Refinement Level | Low to medium | High (USP/BP grade) | Medium to high |

| Intended Use | Technical & mechanical | Wound & burn care | Skin & lip care |

| Additives | May contain stabilizers | None (pure) | May include fragrance |

| Human Contact | Not intended | Safe for all skin types | Safe for external use |

✅ Advantages of Technical petroleum jelly

-

🧱 Excellent Barrier Protection – Shields surfaces from moisture, dust, and air

-

🛢️ Chemical Inertness – Does not react with most materials

-

⚙️ Thermal Stability – Performs well under heat and mechanical stress

-

🧴 Cost-Effective – Affordable alternative to specialty lubricants

-

🔩 Multi-Purpose – One product, dozens of uses

⚠️ Safety & Handling

While Technical petroleum jelly is generally safe when used as intended, follow these precautions:

-

Avoid skin and eye contact during application

-

Do not ingest or use on skin — it is not medical-grade

-

Store in cool, dry conditions

-

Use gloves and goggles when applying in large quantities

-

Keep away from open flames or high-heat sources

📦 Packaging & Supply Options

At Pars Universal Bitumen, we supply high-quality industrial petroleum jelly in bulk quantities:

-

25 kg pails

-

180 kg drums

-

ISO tanks for large-scale supply

-

Custom packaging options available

🌐 Why Choose Industrial Petroleum Jelly from Pars Universal Bitumen?

✔️ Consistent Quality – Manufactured to meet industry standards

✔️ Fast Global Shipping – Timely delivery for projects worldwide

✔️ Custom Formulations – Tailored viscosity, color, or melting point

✔️ Technical Support – MSDS, COA, and compliance documents available

❓ FAQs About Industrial Petroleum Jelly

1. Can industrial petroleum jelly be used on skin?

No. It is not refined for medical or cosmetic use and may contain impurities.

2. What is the shelf life?

Typically 3–5 years if stored in a sealed container away from heat and moisture.

3. Does it expire?

It doesn’t “go bad” but may lose performance quality over time.

4. Can it replace grease?

In light-duty, low-speed applications, yes — but not for high-pressure systems.

5. Is it flammable?

It has a high flash point (>180°C), but keep away from open flame or ignition sources.

Conclusion

Industrial petroleum jelly is a multipurpose, cost-effective material widely used across manufacturing, automotive, electrical, and mechanical industries. Its water-repelling, lubricating, and insulating properties make it indispensable for protecting machinery, extending equipment life, and improving operational efficiency.

Unlike cosmetic or medical-grade variants, Technical petroleum jelly is formulated for robustness, performance, and utility rather than skin application. However, sourcing high-quality, appropriately graded industrial petroleum jelly is crucial to ensure safe and effective use in your operations.

Whether you’re looking to reduce friction in moving parts, protect metal from corrosion, or improve the longevity of your equipment, industrial petroleum jelly is a smart, reliable choice.

📍 Looking to Buy Industrial Petroleum Jelly?

Contact Pars Universal Bitumen Today for Bulk Orders:

📧 Email: [email protected]

📞 Phone: +971 4 878 2031

🌐 Visit: Pub-ltd

Get a quote now – Custom packaging, competitive pricing, and global delivery! If you have any further questions, don’t hesitate to contact us.