What is Cementing Grade Gilsonite?

Cementing Grade Gilsonite is a high-quality, naturally occurring hydrocarbon resin, also known as natural asphalt or uintaite, used as an additive in oil well cementing. It is specially processed to meet the demanding requirements of drilling environments, particularly in high-pressure, high-temperature (HPHT) wells. By enhancing the physical and chemical properties of cement slurries, Gilsonite ensures better zonal isolation, structural support for casing, and long-term well integrity.

In cementing operations, particularly those at great depths or in fragile formations, Cementing Grade Gilsonite improves performance by reducing slurry density, enhancing elasticity, and providing effective sealing capability.

Why Use Cementing Grade Gilsonite in Oil Well Cementing?

Cementing operations are fundamental to the success and safety of any oil or gas well. Poor cementing can lead to gas migration, fluid loss, and ultimately, well failure. Cementing Grade Gilsonite is designed to enhance these operations by improving the overall quality and resilience of the cement sheath. Its use is critical in wells where standard cement slurries are not sufficient to meet environmental and geological challenges.

By integrating Gilsonite into your cement blend, you can tailor the slurry to meet specific operational needs, whether that means minimizing lost circulation, improving bonding, or achieving long-term isolation between zones.

✅ Key Benefits of Cementing Grade Gilsonite

| Benefit | Function in Cementing |

|---|---|

| Lightweight Additive | Reduces slurry density to avoid formation damage and control hydrostatic pressure |

| Thermal Stability | Withstands high temperatures in HPHT wells without degrading |

| Elasticity & Flexibility | Increases cement sheath resilience to thermal and mechanical stress |

| Sealing Capability | Bridges micro-fractures and seals permeable zones to prevent fluid migration |

| Water Resistance | Reduces permeability and prevents water intrusion, improving long-term durability |

1. Lightweight Additive for Reduced Slurry Density

Gilsonite has a low specific gravity (typically around 1.04), making it an excellent material for reducing slurry density without compromising strength. This feature is particularly important when drilling through weak or fractured formations, where high-pressure slurries might cause formation breakdown or fluid loss.

2. Excellent Thermal Stability for HPHT Conditions

Cementing Grade Gilsonite can withstand temperatures exceeding 450°F (232°C), maintaining its structural and chemical stability. This makes it ideal for use in high-pressure, high-temperature wells where many synthetic additives may degrade or lose effectiveness.

3. Flexibility and Enhanced Elasticity

Traditional cement slurries tend to be rigid and brittle. Gilsonite adds flexibility to the cement matrix, allowing it to absorb stress and strain caused by geological movement, pressure changes, or thermal expansion. This reduces the risk of microannulus formation and cracking, which can compromise zonal isolation.

4. Effective Sealing of Micro-Fractures and Porous Zones

Gilsonite acts as a bridging agent in porous and fractured formations, sealing off micro-fractures and minimizing fluid loss. This is particularly useful during primary cementing in naturally fractured zones or formations prone to loss circulation.

5. Improved Water Resistance and Low Permeability

When added to cement, Gilsonite reduces permeability and water absorption, improving the durability of the cement sheath and reducing the risk of gas or fluid migration between formation zones.

Key Properties of Cementing Grade Gilsonite

| Property | Description |

|---|---|

| Specific Gravity | ~1.04 (lighter than most cement additives) |

| Softening Point | 350–450°F (176–232°C), suitable for HPHT environments |

| Fixed Carbon Content | 70–80%, contributes to thermal stability and structural strength |

| Ash Content | Typically below 5%, ensuring purity and minimal contamination |

| Particle Size | Customizable (usually 100–325 mesh) for slurry compatibility |

| Compatibility | Works with Portland cement, retarders, dispersants, and other oilfield cement additives |

Cementing Grade Gilsonite offers unique properties that make it a valuable additive in cementing operations. When added to cement slurries, it provides several benefits such as improved fluid loss control, increased set-cement strength, enhanced durability, and reduced gas migration.

One of the key advantages of Cementing Grade Gilsonite is its ability to control fluid loss in cement slurries. It forms a thin, impermeable filter cake on the wellbore walls, preventing the loss of water and other fluids from the slurry. This helps maintain proper rheological properties and ensures effective zonal isolation during cementing operations.

Furthermore, Gilsonite improves the set-cement strength by acting as a pozzolan. It reacts chemically with the cement, enhancing the development of calcium silicate hydrate (C-S-H) gel, which is responsible for the strength and durability of cementitious materials. This results in a stronger and more reliable cement bond between the casing and the formation, reducing the risk of formation damage and fluid migration.

🛠️ Common Applications of Cementing Grade Gilsonite

| Application | Purpose / Benefit |

|---|---|

| Primary Cementing | Provides zonal isolation and casing support |

| HPHT Wells | Maintains performance under extreme temperature and pressure |

| Loss Circulation Control | Acts as a bridging agent to plug fractures and porous formations |

| Gas Migration Prevention | Enhances sealing to reduce microannulus and prevent gas leaks |

| Lightweight Cement Systems | Used to reduce slurry density in low fracture-gradient formations |

Cementing Grade Gilsonite is a versatile additive suitable for a range of oilfield cementing operations. Its typical applications include:

Primary Oil Well Cementing

Used during the initial casing cementing to provide structural support and zonal isolation.

Loss Circulation Control

Functions as a plugging and bridging agent in formations prone to loss of circulation.

Low-Density Cement Slurries

Ideal for formations with narrow pressure windows where lower slurry weight is required to avoid fracturing the formation.

Gas Migration Prevention

Enhances sealing to prevent post-placement gas migration through the cement column.

Zonal Isolation and Well Integrity

Improves the long-term performance of cement sheaths, especially in HPHT wells, where temperature and pressure fluctuations are common.

Additionally, Cementing Grade Gilsonite helps improve the durability of cemented formations. It provides resistance to chemical attack, including exposure to acids, salts, and other corrosive substances commonly found in well environments. This helps extend the life of the cement sheath and ensures long-term integrity of the wellbore.

Another significant benefit of Cementing Grade Gilsonite is its ability to reduce gas migration. It acts as a sealing agent, effectively sealing off micro-annuli and fractures in the cement sheath, preventing the migration of gases, such as methane or carbon dioxide. This is particularly important in oil and gas wells, where gas migration can lead to production loss, wellbore instability, and environmental issues.

When using Cementing Grade Gilsonite, it is essential to consider the specific well conditions, cement formulation, and desired performance objectives. The dosage and blending process may vary depending on these factors, and it is recommended to follow the manufacturer’s guidelines or consult with experts in cementing operations.

FAQ – Cementing Grade Gilsonite

Q1: Is Gilsonite safe for oil well cementing?

Yes, Gilsonite is a naturally occurring, environmentally friendly material. It is non-toxic and safe to handle, making it a sustainable choice for modern oilfield applications.

Q2: How does Cementing Grade Gilsonite prevent gas migration?

Gilsonite enhances the sealing ability and flexibility of the cement, reducing permeability and preventing the formation of microannuli small channels that can allow gas to migrate after the cement has set.

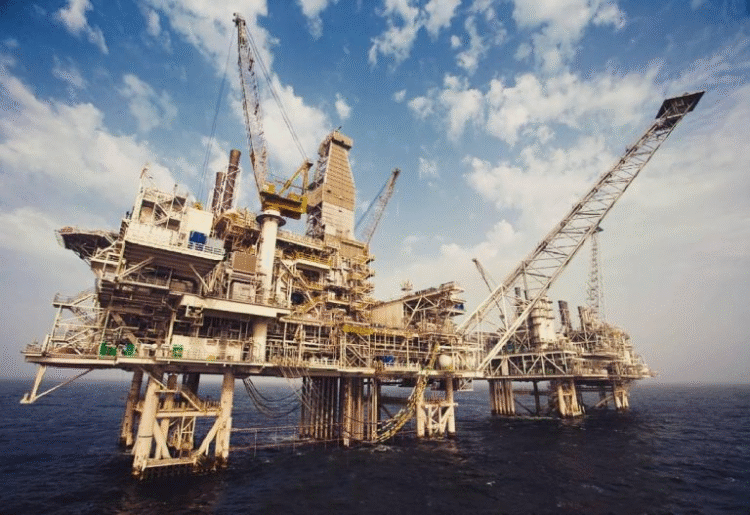

Q3: Can Cementing Grade Gilsonite be used in offshore drilling?

Absolutely. Its water-resistant and high-pressure tolerant properties make it well-suited for both onshore and offshore wells, particularly in deepwater operations with complex geological conditions.

Q4: What other additives work well with Gilsonite in cement slurries?

Cementing Grade Gilsonite is compatible with a wide range of additives, including retarders, fluid loss control agents, dispersants, silica flour (for thermal stability), and latex (for flexibility enhancement).

Conclusion

Cementing Grade Gilsonite is a powerful, multi-functional additive that enhances the performance of oil well cementing operations. With its lightweight nature, exceptional thermal stability, and sealing capabilities, Gilsonite provides essential support in HPHT wells, fractured formations, and loss circulation zones.

In an industry where cementing quality directly impacts well integrity and production safety, using Cementing Grade Gilsonite can significantly improve operational outcomes and reduce long-term risks.

🔥 Ready to enhance your cementing performance with Gilsonite?

Get in touch today to speak with our experts, request a technical data sheet, or receive a custom quote for Cementing Grade Gilsonite tailored to your drilling project. PUB-Ltd as your Cementing Grade Gilsonite Supplier.

📩 [Contact Us Now] or 📞 Call our team of specialists to learn how our premium-grade Gilsonite can boost the strength, flexibility, and reliability of your oil well cementing operations.