Use of Gilsonite for Printing Inks

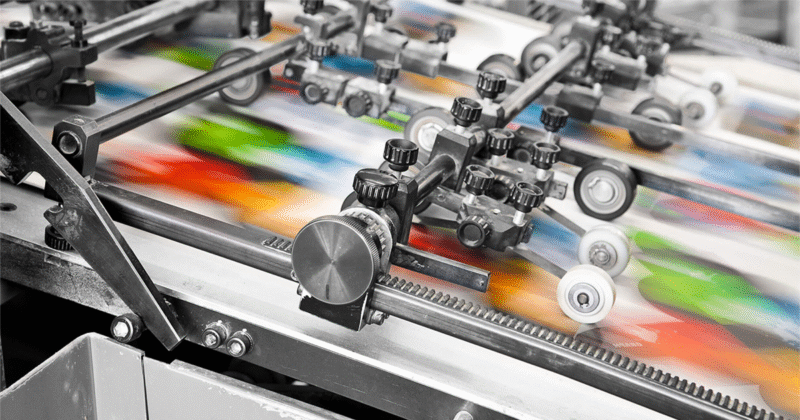

Gilsonite, a naturally occurring hydrocarbon resin, has long been a valuable component in the production of printing inks—particularly for black inks used in newspapers, packaging, and corrugated boxes. Due to its solubility in hydrocarbon solvents and high carbon content, Gilsonite provides deep pigmentation, excellent gloss, fast drying, and strong substrate adhesion. Gilsonite, a natural asphalt product, is also utilized in the printing ink industry for various applications. Its unique properties make it an excellent additive that enhances the performance and quality of printing inks. Let’s explore how Gilsonite is used in printing inks.

Why Gilsonite is Used in Printing Inks

Gilsonite is widely used as a performance-enhancing resin in ink formulations because it offers:

-

Deep black pigmentation

-

High gloss and clarity

-

Rapid drying time

-

Excellent rub resistance

-

Strong adhesion to porous and non-porous substrates

It is especially suitable for letterpress, flexographic, and gravure printing techniques.

Benefits of Gilsonite in Ink Manufacturing

- Deep Color and High Gloss

Gilsonite contributes to a rich, dark black with a glossy finish. This makes it ideal for newspaper ink, where legibility and contrast are critical.

- Fast Drying Time

Its natural solvent compatibility allows for quick drying ink solutions, helping speed up high-volume printing processes.

- Improved Print Quality

Provides sharper definition and better ink laydown, especially on low-cost paper and cardboard.

- Strong Adhesion

Gilsonite helps inks adhere firmly to paper, corrugated board, and certain films, enhancing durability and reducing smudging.

Applications of Gilsonite-Based Inks

🔹 Newspaper Inks

Gilsonite is a preferred additive in newsprint ink formulations, offering low-cost, high-performance printing with strong black tones.

🔹 Packaging and Corrugated Box Inks

It improves print adhesion and clarity on rough or porous materials like kraft paper.

🔹 Plastic Film Printing

When modified, Gilsonite can be used in inks for non-porous substrates like plastic films in flexo and gravure systems.

Gilsonite Properties & Usage for Printing Inks

Viscosity Control:

Gilsonite is commonly used as a viscosity control agent in printing inks. It helps adjust the flow and consistency of the ink, ensuring smooth and consistent application. By incorporating Gilsonite into the ink formulation, manufacturers can achieve the desired viscosity and improve printability on different substrates.

Color Enhancement:

Gilsonite has the ability to enhance the color intensity and depth of printing inks. Its dark color and inherent opacity contribute to richer and more vibrant hues. By incorporating Gilsonite into the ink formulation, printers can achieve more vivid and striking colors in their prints.

Gloss and Sheen:

Gilsonite is known for its natural gloss and sheen properties. When added to printing inks, it enhances the glossiness and shines of the printed materials. This is particularly beneficial for applications where a glossy finish is desired, such as magazines, brochures, and packaging materials.

Ink Adhesion:

Gilsonite improves ink adhesion to various substrates, including paper, cardboard, and certain plastics. It enhances the bonding between the ink and the surface, improving print quality and reducing smudging or smearing. This results in sharper and more defined prints, contributing to overall printing excellence.

UV Resistance:

UV resistance is crucial for printed materials that will be exposed to sunlight or other sources of ultraviolet radiation. Gilsonite offers excellent UV resistance, protecting the printed materials from fading or discoloration over time. This ensures that the prints maintain their vibrancy and durability, even in outdoor or high-UV environments.

Scratch and Abrasion Resistance:

Gilsonite improves the scratch and abrasion resistance of printing inks. It forms a protective barrier on the surface of the printed material, reducing the risk of scratches, scuffs, or wear. This enhances the longevity and durability of the prints, making them more resistant to damage during handling or transportation.

Environmental Benefits:

Gilsonite is a natural product, making it an environmentally friendly choice for printing inks. It is non-toxic and does not contain harmful chemicals. Additionally, Gilsonite can be sourced sustainably, further reducing its environmental impact.

Formulation Considerations

-

Usage Rate: Typically added at 10–25% of the resin portion in solvent-based ink systems.

-

Compatibility: Works with petroleum resins, alkyds, hydrocarbon solvents, and phenolic resins.

-

Best For: Solvent-based inks; not suitable for water-based ink systems without modification.

Frequently Asked Questions (FAQ)

Is Gilsonite used only for black inks?

Primarily, yes. Due to its natural dark color, it’s best suited for black or deep-toned inks.

What printing processes use Gilsonite inks?

Gilsonite-based inks are commonly used in letterpress, flexographic, and gravure printing systems.

Can Gilsonite be blended with other resins?

Yes, it blends well with hydrocarbon and alkyd resins to enhance performance and reduce cost.

Is Gilsonite-based ink environmentally safe?

Gilsonite is a natural material and emits fewer VOCs than many synthetic alternatives, but environmental safety also depends on the full formulation.

Conclusion

In summary, Gilsonite is a valuable additive in the printing ink industry. Its properties as a viscosity control agent, color enhancer, gloss provider, and UV-resistant material make it an ideal choice for enhancing the performance and quality of printing inks. By incorporating Gilsonite into ink formulations, printers can achieve smoother application, more vibrant colors, improved gloss and sheen, enhanced adhesion, increased resistance to UV and abrasion, and environmental sustainability.

Learn how Gilsonite improves printing inks by delivering superior gloss, strong adhesion, fast drying, and rich black pigmentation. Ideal for newsprint and packaging.

-

Fast drying ink solution

-

Deep black ink pigment

-

High gloss printing ink

-

Solvent-compatible ink resin

- UV-resistant black ink

Looking to Improve Ink Quality with Gilsonite?

We provide high-grade Gilsonite for use in printing ink applications.

✔️ Ink manufacturers

✔️ Packaging converters

✔️ Newsprint producers

Contact us for custom sizing, ash content, and packaging. For more information or to place an order, please contact PUB-Ltd sales team @ Contact Us. Our Expert will be in touch with you to guide you about the Use of Gilsonite, that can be produced according to your project requirements. Please Get in touch with us for discussing your project details. PUB-Ltd as your Gilsonite Supplier.