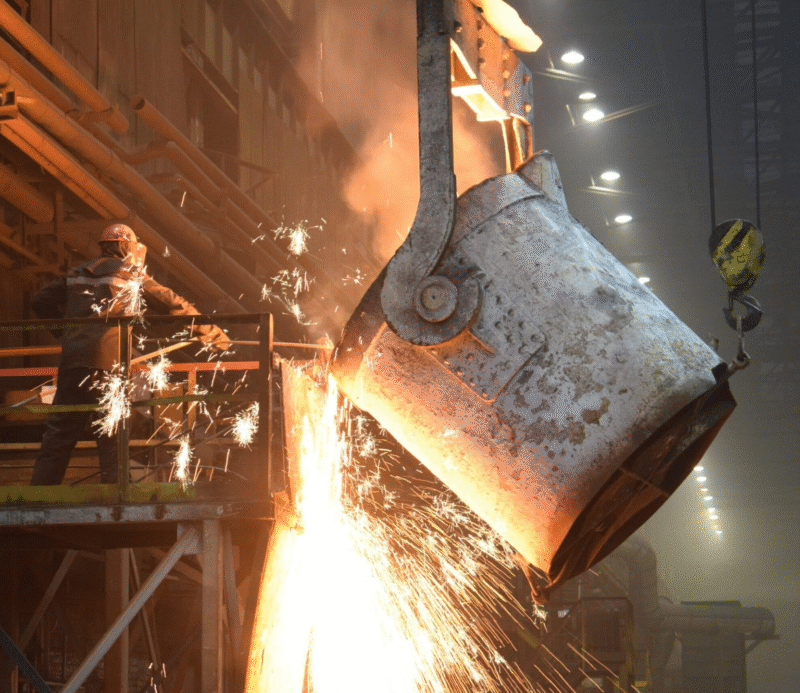

Use of Gilsonite for Foundry and Casting

Gilsonite, a natural asphalt product, is widely used in the foundry and metal casting industry for various applications. Its unique properties make it a valuable additive that enhances mold and core performance, improves casting quality, and provides environmental benefits. Let’s explore how Gilsonite is utilized in foundry and casting processes.

Why Use Gilsonite in Foundries?

Gilsonite is a high-carbon, thermoplastic additive that acts as a lustrous carbon producer during the metal casting process. It helps form a reducing atmosphere in the mold cavity, which prevents metal oxidation and surface imperfections.

Benefits of Gilsonite in Casting Applications

1. Improved Surface Finish

Gilsonite generates lustrous carbon, creating a smooth surface on cast parts and reducing post-processing.

2. Reduction in Casting Defects

It helps prevent common issues such as:

-

Veining

-

Blowholes

-

Pinholes

-

Metal penetration

3. Enhanced Mold Strength

Gilsonite increases the green strength of sand molds, improving mold stability during pouring.

4. Increased Yield

Better mold integrity and fewer defects translate into higher quality castings and reduced scrap rates.

Binder for Sand Molds and Cores:

Gilsonite is a commonly used binder in the foundry industry for making sand molds and cores. When mixed with sand, it forms a durable and heat-resistant binder that holds the sand particles together. This helps create strong and dimensionally stable molds and cores. Gilsonite’s low gas evolution during casting reduces the risk of defects such as gas porosity, ensuring high-quality castings.

Improved Green Strength:

Green strength refers to the strength of a mold or core before it is cured or baked. Gilsonite enhances the green strength of sand molds and cores, allowing them to maintain their shape during handling and pouring. This is particularly important for complex or intricate castings where the mold or core needs to withstand the weight of the molten metal.

Thermal Stability:

Gilsonite exhibits excellent thermal stability, making it an ideal additive for foundry and casting applications. It can withstand high temperatures without significant degradation, ensuring that the mold or core maintains its integrity during the casting process. This thermal stability helps prevent mold or core collapse and ensures accurate reproduction of the desired casting shape.

Reduced Veining and Metal Penetration:

Veining refers to the formation of cracks or lines on the surface of a casting, while metal penetration occurs when molten metal seeps into the sand mold or core. Gilsonite helps reduce veining and metal penetration by forming a barrier between the molten metal and the mold or core. This improves the surface finish of the casting and minimizes defects.

Applications in Metal Casting

Gilsonite is commonly used in the production of:

-

Gray and ductile iron castings

-

Steel castings

-

Precision automotive components

-

Heavy industrial parts

-

Sanitary ware and pipe fittings

How Gilsonite Works in Foundry Sand

During pouring, Gilsonite decomposes at high temperatures, releasing volatile gases that create a reducing atmosphere. This carbon-rich environment coats the mold surface with lustrous carbon, protecting the metal and ensuring smoother finishes.

🔹 Dosage Range: Typically 2%–5% by weight of total sand mix

🔹 Mix Compatibility: Blends well with sea coal, bentonite, and other additives

Advantages Over Traditional Additives

| Property | Gilsonite | Sea Coal |

|---|---|---|

| Carbon Content | High (75–85%) | Lower (45–60%) |

| Smoke & Odor | Lower | Higher |

| Thermal Stability | Excellent | Moderate |

| Surface Finish Quality | Superior | Standard |

Environmental Benefits:

Gilsonite offers environmental benefits in foundry and casting processes. It is a natural product, free from harmful chemicals, making it a sustainable alternative to synthetic binders. Additionally, Gilsonite has a low carbon footprint and is readily available, reducing the environmental impact associated with its production and use.

Improved Shakeout and Sand Reclamation:

Shakeout refers to the process of removing the sand from the casting after it has cooled. Gilsonite aids in the shakeout process by reducing the adhesion of the sand to the casting, making it easier to remove. Furthermore, Gilsonite can be burned off during the casting process, allowing for efficient sand reclamation and reuse, reducing waste and costs.

Frequently Asked Questions (FAQ)

What kind of castings benefit most from Gilsonite?

Iron and steel castings, especially those requiring smooth finishes and low defect rates, benefit significantly from Gilsonite.

Can Gilsonite replace sea coal in foundry sand?

Yes, Gilsonite can replace or reduce the need for sea coal, offering better performance and lower emissions.

Is Gilsonite compatible with green sand systems?

Absolutely. Gilsonite is specifically effective in green sand mold systems used in iron and steel foundries.

Does Gilsonite reduce smoke and odor in the foundry?

Yes. Compared to traditional additives like sea coal, Gilsonite produces less smoke and fewer odors, improving work environment conditions.

Conclusion

In summary, Gilsonite is a valuable additive in the foundry and casting industry. Its properties as a binder, thermal stabilizer, and barrier agent make it an ideal choice for enhancing mold and core performance, improving casting quality, and reducing environmental impact. By incorporating Gilsonite into the foundry process, manufacturers can achieve high-quality castings with improved green strength, reduced defects, and efficient sand reclamation.

Discover how Gilsonite improves sand casting and foundry operations by enhancing mold strength, surface finish, and reducing casting defects like veining and blowholes.

-

Foundry mold performance enhancer

-

High-carbon sand additive

-

Lustrous carbon mold coating

-

Casting surface finish improver

-

Green sand strength booster

Looking for High-Quality Foundry-Grade Gilsonite?

We supply premium Gilsonite tailored for foundry applications, helping you improve casting yield, reduce rework, and meet quality standards. Contact us for custom sizing, ash content, and packaging. For more information or to place an order, please contact PUB-Ltd sales team @ Contact Us.

Our Expert will be in touch with you to guide you about the Use of Gilsonite, that can be produced according to your project requirements. Please Get in touch with us for discussing your project details. PUB-Ltd as your Gilsonite Supplier.