🛢️ Use of Base Oil in Lubricant & Industrial Applications

Base oil plays a critical role in the production of lubricants, greases, and other petroleum-based products. As the foundational ingredient in many formulations, it directly affects the performance, stability, and efficiency of the final product. This post explores the use of base oil across various sectors, detailing its types, properties, and applications in depth.

Indeed, base oil remains essential for reducing friction, enhancing efficiency, and lengthening equipment life. Moreover, it supports cleaner operations by improving energy savings and lowering emissions.

🧪 What Is Base Oil?

Base oil—the main fluid in lubricants and greases—carries additives that reduce wear, clean surfaces, and control temperature. It typically originates from crude oil through refining methods like solvent extraction or hydrocracking. Alternatively, industries may use synthetic variants. Overall, base oil comprises 80–90% of final lubricant volume.

In essence, it delivers key properties (viscosity, stability, flow), while additives fine-tune performance for specific uses.

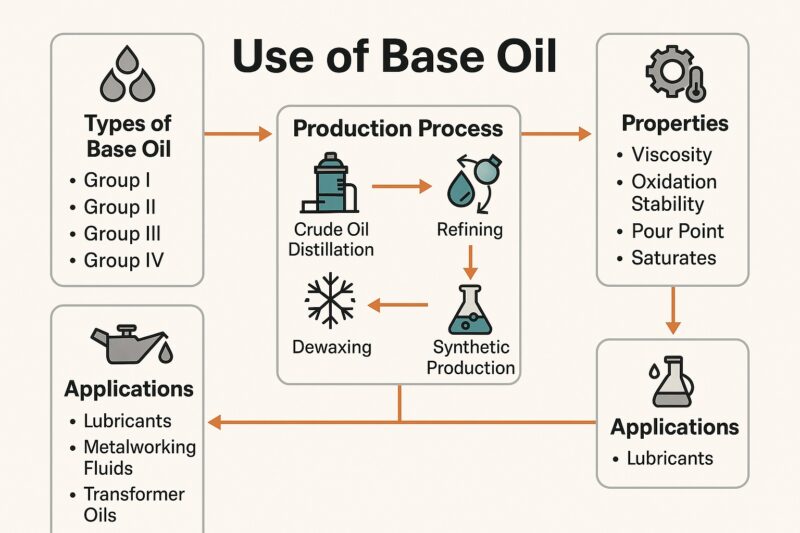

⚙️ Production Process of Base Oil

The production of base oil begins with crude oil distillation, followed by several refining steps. Each step enhances its quality. These include:

-

Solvent Extraction – removes unwanted aromatics.

-

Hydrotreating – saturates the oil and reduces sulfur.

-

Dewaxing – improves low-temperature flow.

-

Hydrocracking (Group II and III) – yields highly stable, pure oils.

-

Synthetic Production (Group IV and V) – uses chemical synthesis (e.g., PAOs, esters) for advanced applications.

Each refining stage enhances the oil’s performance characteristics to match industrial standards.

📊 Technical Specifications

| Property | Group I | Group II | Group III | Group IV (PAO) | Group V (Esters, etc.) |

|---|---|---|---|---|---|

| Saturates (%) | <90 | ≥90 | ≥90 | ~100 | Varies |

| Sulfur Content (%) | >0.03 | ≤0.03 | ≤0.03 | ~0 | Varies |

| Viscosity Index (VI) | 80–120 | 90–120 | ≥120 | 125–160 | Varies |

| Oxidation Stability | Moderate | Good | Excellent | Very High | High |

| Pour Point (°C) | -6 to -12 | -9 to -15 | -18 to -25 | -40 or lower | Depends on type |

These properties determine how each oil type behaves under various temperature and pressure conditions..

🔍 Key Roles

These oils delivers critical functions in lubrication systems:

-

Lubricates: Reduces metal-on-metal wear

-

Cools: Helps dissipate heat from moving parts

-

Protects: Prevents corrosion and rust

-

Preserves seals: Maintains rubber component integrity

-

Supports materials: Avoids damage to plastics and metals

Furthermore, using high-grade base oil enhances:

✅ equipment reliability

✅ cold-start performance

✅ thermal resilience

🏭 Industrial Use of Base Oil

1. 🛠️ Lubricant Formulations

Base oil is the primary ingredient in automotive and industrial lubricants. It supports:

- Engine oils

- Gear oils

- Hydraulic fluids

- Compressor oils

The specific type of oil influences viscosity, lubricity, and thermal resistance.

2. 🏛️ Metalworking Fluids

Used as a carrier fluid and coolant in cutting, grinding, and milling operations. It:

- Reduces tool wear

- Minimizes heat generation

- Ensures surface finish quality

3. ⚙️ Transformer Oils

Highly refined base stocks from Group II or III are used in electrical transformers to:

- Insulate components

- Dissipate heat

- Resist oxidation and sludge formation

4. 🧪 Process Oils

These oils are widely used in:

- Rubber manufacturing

- Plasticizer blends

- Adhesives and sealants

Process oils improve flexibility and compatibility with polymers.

5. 🚗 Automotive Applications

Synthetic base stocks (Group IV and V) are essential in:

- High-performance engine oils

- Racing lubricants

- Transmission fluids

They offer excellent thermal and oxidative stability under extreme conditions.

6. 🏣 Grease Manufacturing

In grease production, refined oils are mixed with thickeners (like lithium soaps) to form:

- Automotive greases

- Industrial machinery lubricants

- Marine applications

The base fluid’s consistency affects the final grease grade (NLGI classification).

🌱 Benefits of High-Quality Base Oils

-

Boosts oxidation resistance for extended oil life

-

Enhances thermal stability under extreme conditions

-

Reduces wear and energy losses

-

Provides reliable cold-start capability

-

Meets or exceeds environmental regulations

🔧 Properties & Performance

-

Viscosity: Ensures proper flow; different viscosities suit different systems

-

Viscosity Index (VI): High VI keeps viscosity consistent across temperatures

-

Oxidation Resistance: Protects against breakdown at high heat

-

Low-Temp Flow: Ensures lubrication in cold starts

-

Thermal/Chemical Stability: Resists degradation

-

Additive Compatibility: Works with detergents, anti-wear agents, and rust inhibitors

❓ FAQs About the Use of Base Oil

🔍 What is base oil made from?

It is typically derived from refined crude oil or synthetic chemical compounds. Refining removes impurities and enhances its performance.

⚙️ How is base oil different from motor oil?

Motor oil is a finished product made by blending base oil with additives like detergents, anti-wear agents, and antioxidants.

🧪 Which industries use base oil the most?

The largest consumers include:

- Automotive

- Heavy machinery

- Power generation

- Chemical manufacturing

🛠️ What are the benefits of synthetic base oils?

They offer:

- Greater oxidation resistance

- Better cold flow

- Extended service life

- Cleaner engine operation

🔃 What role does viscosity play in base oil?

Viscosity impacts:

- Lubrication film thickness

- Friction control

- Heat dissipation

Different applications require specific viscosity ranges.

🧾 Conclusion

Base oil is the foundation of modern lubrication technology, impacting multiple industrial and automotive sectors. From enhancing machine efficiency to reducing wear and tear, its properties define product quality and performance. As technology advances, the demand for high-quality Group II, III, and synthetic base stocks continues to grow. Whether used in hydraulic systems, transformers, or gearboxes, base oil remains essential in keeping industries moving smoothly.

📣 Call to Pars Universal Bitumen

🔍 Looking for reliable base oil for your industrial or lubricant needs?

👉 Pars Universal Bitumen offers a full range—from Groups I to V:

✅ Solvent-refined and hydrocracked grades

✅ High-performance synthetic and biodegradable options

✅ Full technical support, test data, and compliance documentation

✅ Custom packaging and global logistics

📞 Contact us today:

📞 +971 4 878 2031

🌐 PUB-Ltd.

🌍 Choose Pars Universal Bitumen to enhance machinery performance, prolong oil intervals, and meet sustainability goals. If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.