Gilsonite for Oil and Gas Industry | Applications & Benefits

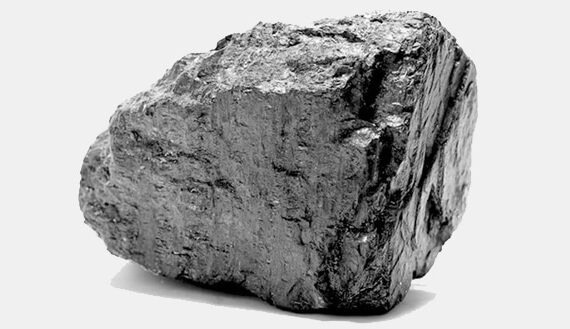

Gilsonite, a naturally occurring solid hydrocarbon, has found numerous applications in the oil and gas industry. Its unique properties make it a valuable resource for enhancing various operations in this sector. In this article, we will explore the applications and benefits of Gilsonite in the oil and gas industry, focusing on its relevance and impact on different processes.

Key Properties of Gilsonite

-

🧪 High carbon and asphaltene content

-

💧 Insoluble in water, soluble in hydrocarbons

-

🔥 High softening point and thermal stability

-

🧱 Low specific gravity (lightweight additive)

-

🛢️ Excellent bonding and sealing characteristics

Applications of Gilsonite in Oil & Gas

Wellbore Stability and Drilling Fluids

Gilsonite is used in oil-based and water-based drilling muds to:

-

Reduce differential sticking

-

Prevent shale swelling and sloughing

-

Control fluid loss in porous formations

-

Improve lubricity and mud stability

✅ Benefit: Enhances drilling efficiency and prevents costly wellbore instability.

One of the key applications of Gilsonite in the oil and gas industry is its use in wellbore stability and drilling fluids. Gilsonite, when added to drilling fluids, can improve their viscosity and thermal stability, allowing for efficient drilling operations.

It helps prevent wellbore instability by forming a sealant and reducing fluid loss, ensuring the integrity of the wellbore during drilling.

Cementing and Lost Circulation Control

As a lightweight additive in cement slurries, Gilsonite:

-

Lowers slurry density

-

Improves flexibility and bonding

-

Helps maintain zonal isolation

-

Minimizes micro-annulus formation

✅ Benefit: Ensures better cement integrity and long-term well sealing.

Natural asphalt is also used in cementing operations in the oil and gas industry. When added to cement slurries, it improves the set-cement properties, enhances bonding strength, and reduces the risk of lost circulation.

Lost circulation occurs when drilling fluids escape into porous formations, leading to reduced drilling efficiency. Gilsonite acts as a bridging agent, sealing off fractures and preventing fluid loss.

Gilsonite is an effective loss circulation material (LCM):

-

Plugs fractures and vugular formations

-

Forms a thin, resilient filter cake

-

Works under high differential pressures

✅ Benefit: Reduces non-productive time and loss of expensive fluids.

Asphaltene and Paraffin Control

Asphaltene and paraffin deposition are common challenges in the oil and gas industry. These deposits can lead to reduced flow rates, blockages, and decreased production efficiency.

Gilsonite, with its high carbon content and solvency properties, can be used as an additive to control and mitigate the formation of asphaltene and paraffin deposits.

Sealing and Repairing Applications

Gilsonite’s unique properties make it an ideal choice for sealing and repairing applications in the oil and gas industry. It can be used to seal fractures, cracks, and leaks in wellbores and pipelines.

Gilsonite-based products provide a durable and long-lasting seal, ensuring the integrity and safety of oil and gas infrastructure.

Advantages of Using Gilsonite in Oilfield Operations

-

🟢 Eco-Friendly: Naturally occurring and non-toxic

-

💰 Cost-Effective: Reduces overall fluid and cement usage

-

🏗️ High Performance: Suitable for HPHT (High Pressure, High Temperature) wells

-

🔄 Compatible: Works with oil-based and water-based systems

Frequently Asked Questions (FAQ)

What is Gilsonite used for in drilling?

Gilsonite reduces fluid loss, stabilizes shale, and improves the lubricity and performance of drilling mud.

Can Gilsonite be used in all cementing jobs?

Yes, especially in wells where reduced slurry weight and enhanced flexibility are required.

Is Gilsonite safe to handle?

Yes. It is non-hazardous, non-toxic, and safe for use under proper industrial guidelines.

Does Gilsonite work in high-temperature environments?

Yes. Gilsonite has a high softening point and is stable under HPHT conditions.

Conclusion

Gilsonite plays a significant role in enhancing various operations in the oil and gas industry. Its applications range from wellbore stability and drilling fluids to cementing, lost circulation control, and controlling asphaltene and paraffin deposits. Additionally, Gilsonite can be used for sealing and repairing critical infrastructure.

Explore how Gilsonite enhances oil and gas operations. Learn about its uses in drilling, cementing, and fluid loss control to boost performance and efficiency.

-

Gilsonite in drilling mud

-

Natural asphalt for oilfield

-

Gilsonite cement additive

-

Lost circulation materials

-

Uintaite in oil and gas

Contact Pars Universal Bitumen-Ltd for Gilsonite Supply & Technical Support

We supply high-quality Gilsonite tailored for oilfield applications. Contact us for custom sizing, ash content, and packaging. For more information or to place an order, please contact Pars Universal Bitumen-Ltd sales team @ Contact Us.

Our Expert will be in touch with you to guide you about the Use of Gilsonite, that can be produced according to your project requirements. Please Get in touch with us for discussing your project details. Pars Universal Bitumen-Ltd As Your Gilsonite Supplier