Gilsonite for Printing Inks | Boost Gloss & Durability Naturally

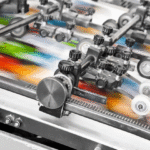

Gilsonite, also known as Natural bitumen or Uintaite, is a versatile, naturally occurring hydrocarbon resin widely used in printing ink formulations. Its excellent gloss, adhesion, and compatibility with solvents make it ideal for producing high-performance black inks, especially for gravure, flexographic, and offset printing.

Why Use Gilsonite in Printing Inks?

Gilsonite offers multiple advantages in ink manufacturing:

-

Provides deep, rich black pigmentation

-

Enhances gloss and finish

-

Improves adhesion to non-porous surfaces

-

Speeds up drying time

-

Offers a cost-effective alternative to petroleum resins

The need for additives in printing inks

Printing inks are complex formulations that require the addition of various additives to achieve desired characteristics and performance. These additives can enhance ink flow, drying time, color intensity, and other important properties. Natural bitumen is one such additive that is used in printing inks to improve their performance and provide specific benefits.

Properties of Gilsonite that make it suitable for printing inks

Gilsonite possesses several properties that make it an ideal additive for printing inks. It has a high carbon content, which contributes to its excellent black color and opacity. It also has a low softening point, allowing it to melt and flow easily during the printing process. Additionally, Natural bitumen has good adhesion properties, which help the ink adhere to various substrates.

Gilsonite Applications in Ink Formulations

1. Newspaper and Publication Inks

-

Used in black news inks for high-speed printing

-

Provides excellent printability and coverage

2. Packaging Inks

-

Used for corrugated boxes, paper bags, and labels

-

Adds smudge resistance and crisp finish

3. Flexographic & Gravure Inks

-

Used on plastic films, aluminum foil, and synthetic papers

-

Natural bitumen enhances adhesion and solvent compatibility

Benefits of using Gilsonite for Printing Ink

The use of Gilsonite in printing inks offers several benefits:

Improved print quality:

Natural bitumen enhances the color intensity and depth of printing inks, resulting in vibrant and visually appealing prints.

Enhanced durability:

Gilsonite improves the resistance of printing inks to abrasion, water, and chemicals, making the prints more durable and long-lasting.

Faster drying time:

Natural bitumen promotes faster drying of the ink, reducing the risk of smudging and enabling faster production speeds.

Enhanced ink flow:

Gilsonite improves the flow properties of printing inks, ensuring smooth and consistent application on various substrates.

Cost-effective:

Natural bitumen is a cost-effective additive compared to other alternatives, making it an attractive choice for ink manufacturers.

Printing Processes and Gilsonite

Compatibility with different printing processes

Natural bitumen is compatible with various printing processes, including offset printing, flexographic printing, gravure printing, and screen printing. Its low softening point allows it to melt and flow easily during the printing process, regardless of the printing method used.

Application methods and considerations

Gilsonite can be added to printing inks during the ink manufacturing process. It is typically incorporated into the ink formulation at a specific percentage, depending on the desired properties and performance requirements. Ink manufacturers need to consider the type and concentration of Natural bitumen to ensure optimal results and avoid any negative effects on the ink’s stability and performance.

Environmental Considerations

Environmental impact and sustainability

Gilsonite is a naturally occurring material and is considered to be relatively environmentally friendly compared to some synthetic additives used in printing inks. However, it is essential to ensure responsible sourcing and extraction practices to minimize any potential environmental impact.

Compliance with regulations

In the printing industry, there are regulations and guidelines that govern the use of additives in printing inks. Ink manufacturers must ensure compliance with relevant regulations, such as those related to volatile organic compounds (VOCs) and heavy metals, to ensure the safety of the end product and protect the environment.

Frequently Asked Questions (FAQ)

Why is Gilsonite used in printing inks?

Natural bitumen provides high gloss, quick drying, and deep color in ink formulations—especially black inks for high-speed printing.

What types of inks use Gilsonite?

Primarily used in black news inks, packaging inks, flexographic, and gravure inks, especially where solvent-based systems are needed.

Is Natural bitumen safe for printing applications?

Yes. Natural bitumen is a naturally occurring, non-toxic material that is widely used in industrial ink formulations.

Can Gilsonite replace synthetic resins in inks?

Yes. It is often used as a cost-effective substitute for petroleum resins, offering similar or better performance.

Conclusion: Gilsonite for Printing Ink

Natural bitumen is a valuable additive in the printing ink industry, offering a range of benefits that improve print quality, durability, and production efficiency. Its unique properties make it well-suited for various printing processes, and its cost-effectiveness adds to its appeal.

As with any additive, proper formulation and compliance with regulations are crucial to ensure optimal performance and environmental responsibility. By leveraging the advantages of Gilsonite, ink manufacturers can enhance their products and meet the evolving needs of the printing industry.

Explore the benefits of using Gilsonite in printing ink formulations. Enhance gloss, adhesion, and drying speed with this eco-friendly natural resin.

-

Gilsonite in black printing inks

-

Natural asphalt resin for inks

-

Uintaite ink binder

-

Gloss enhancer for ink

-

Eco-friendly black pigment resin

Contact Pars Universal Bitumen-Ltd for Gilsonite for Inks

Looking for premium-grade Gilsonite for ink manufacturing?

We supply high-quality Natural bitumen tailored for oilfield applications. Contact us for custom sizing, ash content, and packaging. For more information or to place an order, please contact Pars Universal Bitumen-Ltd sales team @ Contact Us.

Our Expert will be in touch with you to guide you about the Use of Gilsonite, that can be produced according to your project requirements. Please Get in touch with us for discussing your project details. PUB-Ltd As Your Gilsonite Supplier.