🛢️ Use of Industrial Petroleum Jelly

Industrial petroleum jelly also known as Industrial-grade Petrolatum, plays a crucial role in maintaining the smooth operation of machinery and equipment across many industries. Its unique properties—such as excellent lubrication, moisture resistance, and protective barriers—help reduce wear, prevent corrosion, and extend equipment life. As industries face harsher working conditions and higher performance demands, the importance of reliable materials like industrial petroleum jelly continues to grow.

This blog explores its applications, benefits, and why it remains an essential component in industrial maintenance and manufacturing.

What is Industrial Petroleum Jelly?

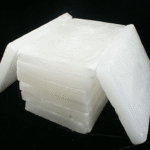

Industrial petroleum jelly is a semi-solid mixture of hydrocarbons derived from petroleum refining, specifically formulated for industrial purposes. Unlike cosmetic grades, this jelly contains additives tailored to meet the needs of mechanical, manufacturing, and maintenance applications.

Its thick, lubricating consistency, resistance to oxidation, and water-repellent properties make it an essential material for protecting equipment and improving manufacturing processes.

Composition and Physical Properties of Industrial Petroleum Jelly

Industrial-grade Petrolatum is a semi-solid mixture primarily made of saturated hydrocarbons derived from petroleum refining. Its distinct physical and chemical properties make it essential for various industrial uses. Understanding its composition and physical features helps industries select the best grade for their needs.

Composition

Industrial petroleum jelly mainly contains:

-

Paraffinic hydrocarbons (alkanes): These long-chain saturated hydrocarbons form the base matrix, giving petroleum jelly its semi-solid texture.

-

Isoparaffinic hydrocarbons: Branched saturated hydrocarbons that contribute to the product’s softness and spreadability.

-

Cycloparaffins (naphthenes): Cyclic hydrocarbons that improve stability and oxidation resistance.

-

Aromatic hydrocarbons: Present in very small amounts, these influence color and chemical traits.

-

Additives: Industrial grades may include antioxidants, corrosion inhibitors, and viscosity modifiers to enhance performance.

The refining process removes impurities like sulfur, nitrogen compounds, and heavy metals, ensuring the jelly’s stability and safety in industrial environments.

Physical Properties

Key physical properties include:

-

Appearance: Semi-solid, translucent to opaque, with a smooth feel.

-

Color: Light yellow to amber, varying with refining and additives.

-

Melting Point: Ranges from 38°C to 60°C (100°F to 140°F), providing stability under industrial temperature conditions.

-

Penetration: Measures firmness; typically ranges from 100 to 400 (0.1 mm units).

-

Viscosity: High viscosity ensures excellent lubrication and adhesion.

-

Solubility: Insoluble in water but dissolves in organic solvents like hexane and benzene.

-

Flash Point: High, above 230°C, which makes it safe for industrial handling.

-

Specific Gravity: Between 0.85 and 0.95 at 20°C, indicating a lightweight material.

These characteristics allow industrial petroleum jelly to serve effectively as a lubricant, moisture barrier, and protective coating in demanding conditions.

📊 Table: Composition and Physical Properties of Industrial Petroleum Jelly

| Property | Typical Range / Description | Unit / Notes |

|---|---|---|

| Paraffinic Hydrocarbons | 60 – 80% | Weight % |

| Isoparaffinic Hydrocarbons | 15 – 30% | Weight % |

| Cycloparaffins (Naphthenes) | 5 – 10% | Weight % |

| Aromatic Hydrocarbons | <1% | Weight % |

| Appearance | Semi-solid, translucent to opaque | Visual |

| Color | Light yellow to amber | Visual |

| Melting Point | 38 – 60 | °C |

| Penetration (cone test) | 100 – 400 | 0.1 mm units |

| Viscosity | High viscosity; gel-like | Qualitative |

| Solubility | Insoluble in water; soluble in organic solvents | Qualitative |

| Flash Point | >230 | °C |

| Specific Gravity | 0.85 – 0.95 | at 20°C |

⚙️ Production and Processing of Industrial Petroleum Jelly

The production process of industrial-grade petrolatum starts with crude oil distillation. Refiners extract hydrocarbon fractions, then subject the material to controlled processing and blending with performance-enhancing additives. This process ensures stability under extreme temperatures and resistance to chemical degradation.

Finally, the jelly is packaged in bulk containers, drums, or tubs, designed for industrial handling and easy application.

🏭 Industrial Applications of Petroleum Jelly

Industrial petroleum jelly serves numerous roles across many sectors. Here are the primary applications:

🔧 Lubrication for Machinery and Equipment

It reduces friction and wear in moving parts such as gears, chains, and bearings. Its thick texture adheres well under pressure, providing long-lasting lubrication.

🛠️ Corrosion Protection

Applied on metal surfaces, it forms a protective barrier that repels moisture and prevents rust. This is especially useful in marine, automotive, and construction equipment.

⚙️ Sealant and Insulator

Used in electrical equipment and cable joints, petroleum jelly prevents moisture ingress and maintains electrical insulation.

🚜 Agricultural Machinery Maintenance

It protects farming tools and machinery exposed to harsh environments, ensuring smooth operation and longer service life.

🏭 Manufacturing and Assembly Processes

It acts as a release agent for molds and stamping dies, helping parts separate cleanly without damage.

📦 Packaging Protection

Applied to metal packaging components, it prevents corrosion during storage and transport.

✅ Advantages of Industrial Petroleum Jelly

-

Provides effective lubrication under high pressure and varying temperatures.

-

Protects metals from rust and corrosion.

-

Acts as a moisture barrier and insulator.

-

Chemically stable and resistant to oxidation.

-

Cost-effective and easy to apply.

-

Enhances equipment longevity and reduces maintenance needs.

❓ FAQs About Industrial Petroleum Jelly

Q1: What is industrial-grade petrolatum mainly made of?

Industrial petroleum jelly primarily consists of saturated hydrocarbons, such as paraffinic and isoparaffinic compounds. These components provide a smooth, semi-solid texture that suits a wide range of industrial uses.

Q2: How does the melting point affect industrial use?

Because its melting point ranges between 38°C and 60°C, industrial petroleum jelly remains stable under varying temperatures. As a result, it works effectively for lubrication and protection in different environments.

Q3: Is industrial petroleum jelly safe to handle?

Yes, it is safe when used properly. The product has a high flash point above 230°C, which significantly reduces the risk of fire, making it suitable for many industrial settings.

Q4: Can additives improve industrial petroleum jelly’s performance?

Certainly! Additives like antioxidants and corrosion inhibitors enhance durability and extend the product’s lifespan. Consequently, it better meets specific industrial requirements.

Q5: What industries benefit most from using industrial petroleum jelly?

Industries such as machinery manufacturing, metalworking, electrical insulation, and corrosion protection greatly benefit. Moreover, its moisture barrier properties help in packaging and sealing applications.

Q6: How does petroleum jelly interact with water and solvents?

Industrial-grade petrolatum is water-resistant, which makes it an excellent moisture barrier. However, it dissolves in organic solvents, facilitating cleaning and formulation processes.

🧾 Conclusion- Use of Industrial Petroleum Jelly

Industrial petroleum jelly is an essential material across many industries. Due to its unique composition, it offers reliable performance in lubrication, protection, and sealing applications. Additionally, its stable melting point and high flash point ensure safe and effective use in various conditions.

Moreover, the inclusion of additives improves its durability, allowing it to fulfill specific industrial needs. Its water-resistant nature protects machinery and equipment from moisture damage, enhancing operational efficiency. Therefore, industrial-grade petrolatum remains a trusted choice for industries seeking reliable and versatile solutions.

📞 Contact Pars Universal Bitumen

Looking for high-quality industrial petroleum jelly tailored to your operational needs?

👉 Pars Universal Bitumen supplies premium industrial petroleum jelly for lubrication, corrosion prevention, and manufacturing support.

-

Bulk supply with consistent quality

-

Technical assistance and documentation

-

Timely global delivery

📧 Email: [email protected]

📞 Phone: +971 4 878 2031

🌐 Visit: Pub-ltd

📩 Trust Pars Universal Bitumen as your reliable partner in industrial materials. If You have any other Query or Question you want to ask, Please don’t hesitate to Contact Us.